Rev 2 1 7 02 2020 tensile stress mpa strain 0 200 400 600 800 1000 1200 1400 0 0 02 0 04 0 06 0 08 0 10 mim 1 ph ss rouht 1 ph ss marore 1 ph ss all data and graphs on front page reflect values of h900 heat treated 17 4 ph ss.

17 4 stainless steel microstructure.

Structure evolution of type 17 4 ph stainless steel during long term aging at.

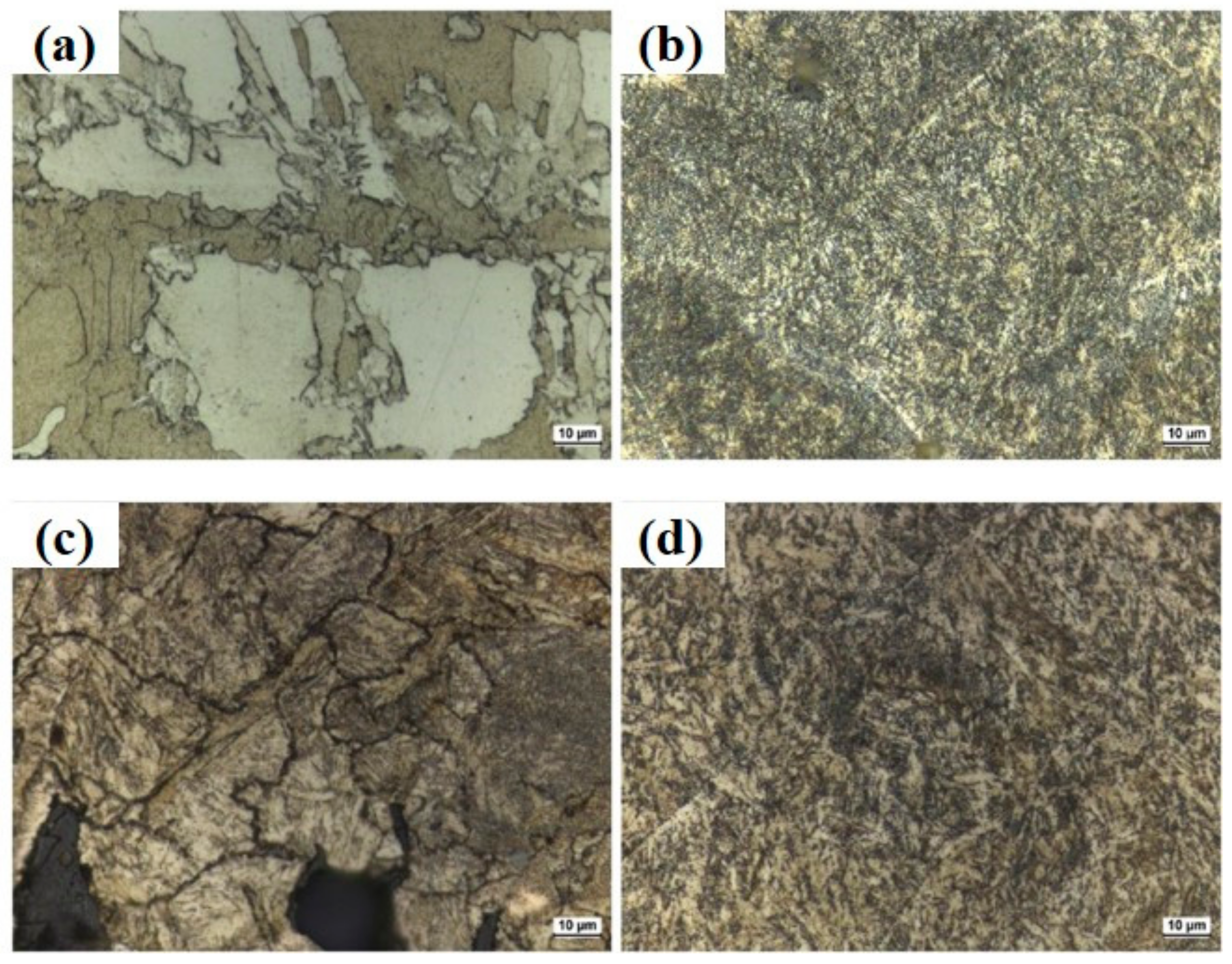

The microstructures and mechanical properties of 17 4 ph stainless steel at each steps of heat treatment such as homogenizing solid solution treatment followed by aging treatment longterm aging at 400 c and recovery treatment in order to obtain a better understanding of the embrittlement phenomena on aging was investigated.

Moreover the x ray diffraction xrd technique was applied to indentify the phase structure crystal plane arrangement and the metal grain size in the usr treated surface.

Microstructure of 17 4 ph stainless steel.

Unlike conventional martensitic stainless steels such as type 410 17 4 is quite weldable.

Materials science and engineering a 1988.

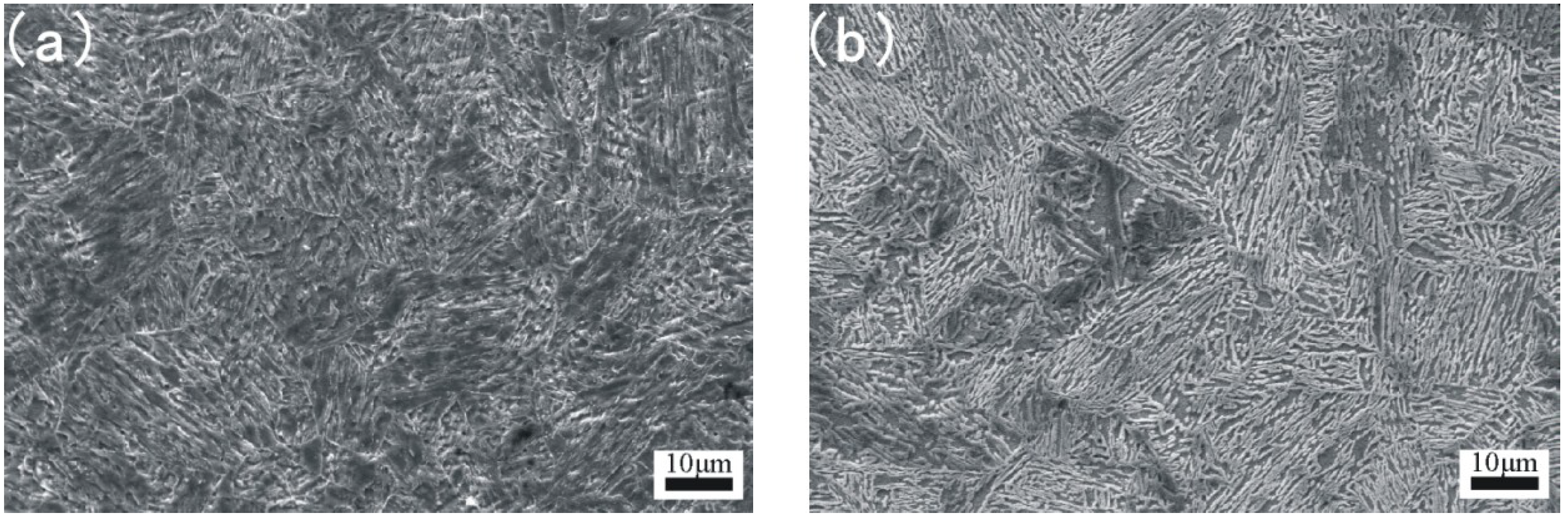

The microstructure evolution of usr treated 17 4ph stainless steel and the surface modification layer were observed and analyzed in detail.

It is further strengthened by a low temperature treatment which precipitates a copper containing phase in the alloy.

J chem phys 1972.

Wang j zou h li c peng yh qiu s shen b.

Type 17 4 ph stainless steel is the most widely used of all of the precipitation hardening stainless steels.

As with other precipitation hardening alloys al 17 4 pre cipitation hardening alloy is more susceptible to stress.

As the homogenizing treatment time increased the length of δ.

Hardening is achieved by a short time simple low temperature treatment.

The microstructure of 17 4 ph stainless steel at various stages of heat treatment i e after solution heat treatment tempering at 580 c and long term aging at 400 c have been studied by.

In gen eral the corrosion resistance of al 17 4 alloy is supe rior to that of the hardenable 400 series stainless steels.

Viswanathan r banerjee s krishnan r.

The microstructure and microhardness of the laser ss processed part will be analyzed.

Effects of aging on the 13.

It is also known as 630 stainless steel.

17 4 stainless is an age hardening martensitic stainless combining high strength with the corrosion resistance of stainless steel.

Produced 17 4ph stainless steel ss parts.

While the powder used was gas atomized 17 4ph stainless steel with a.

17 4 ph mim standard stainless steel heat treated to h900 specification.

It includes the addition of chromium nickel copper and niobium making it a truly martensitic microstructure.

Xperimental m ethod the substrate used in this research was 316 stainless steel coupons with dimension of 100 100 10 mm.